- Home

-

Products

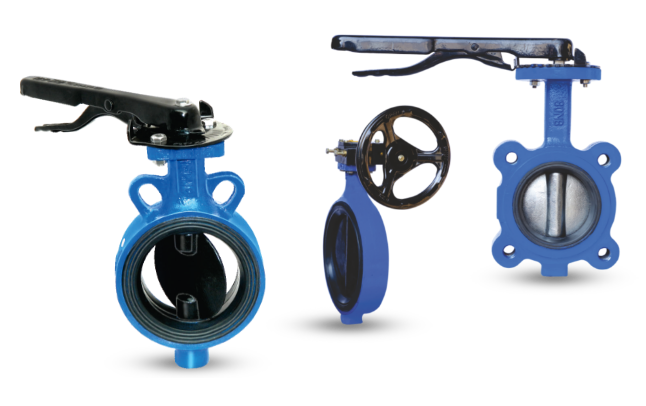

Valves Supplier

MetaForge Industries provides a comprehensive range of high-performance valves designed for precision flow control across industrial applications.

Gauges, Switches & Transmitters

We supply reliable pressure and temperature gauges, switches, and transmitters engineered for accuracy and durability in demanding environments.

Hoses

Our industrial hoses are selected for superior flexibility, pressure resistance, and durability.

Couplings / Hose Fittings

MetaForge offers a broad portfolio of quick connect/disconnect couplings and hose fittings ensuring secure and leak-proof performance in various operating conditions.

Flanges

Our flange collection includes weld neck, slip-on, blind, threaded, and lap joint types used to connect pipes, valves, pumps, and other system components.

Pipes & Semi-Finished Metals

We stock and supply a range of seamless and welded pipes along with semi-finished metallic materials for industrial fabrication and pipeline construction.

Butt Weld Fittings

We provide a complete range of butt weld fittings—elbows, tees, reducers, and caps—manufactured to international standards for secure and durable pipeline connections.

Forged High Pressure Pipe Fittings

Our forged fittings are designed for high-pressure applications, ensuring strength, dimensional accuracy, and resistance to mechanical stress.

Grooved Fittings

We offer grooved fittings for fire protection, HVAC, and water systems, facilitating quick installation and reliable performance.

GI & SS Low Pressure Fittings

MetaForge supplies galvanized iron and stainless-steel fittings suitable for low-pressure systems, ensuring corrosion resistance and easy maintenance.

- About Us

- Gallary

- Contact Us